Fraunhofer Institute for Physical Measurement Techniques IPM

The "Thermal Energy Converters" department at Fraunhofer IPM characterizes and integrates materials with special physical properties into systems: for more than 20 years, one research focus has been in the field of thermoelectric materials, which allow direct conversion of waste heat into electric current, as well as in the reverse application as solid-state-based cooling and temperature control systems.

Due to this long expertise in the field of thermoelectrics, also built up by publicly funded (e.g. BMWi projects "thermoHEUSLER" and "thermoHEUSLER2", EU project "HeatReCar", BMBF project "TEG2020" etc.) as well as industrial projects, Fraunhofer IPM is one of the world's leading groups in the field of thermoelectrics. Activities include module assembly and interconnection technology, the development of thermoelectric generator (TEG) systems for waste heat recovery and self-sufficient energy supply applications, the integration of Peltier modules in various cooling and temperature control systems, and the development of measuring systems and the construction of measuring stations to determine the thermoelectric properties of materials and modules. At Fraunhofer IPM, thermal and thermoelectric simulations of components as well as systems and their assembly are established fields of work in addition to the various areas of assembly and connection technology for module manufacture and PD measurement technology. Within the framework of various projects, Fraunhofer IPM has been able to develop a semi-automated assembly and interconnection technology for modules. Fig. 1 shows a setting robot for this module production.

With regard to thermal coupling, alternatives to the usual planar design of Peltier elements are sometimes required. For this purpose, thermoelectric strips have been used in several projects both as a generator and as a Peltier module. With this concept, tubular structures can also be coupled close to the contour.

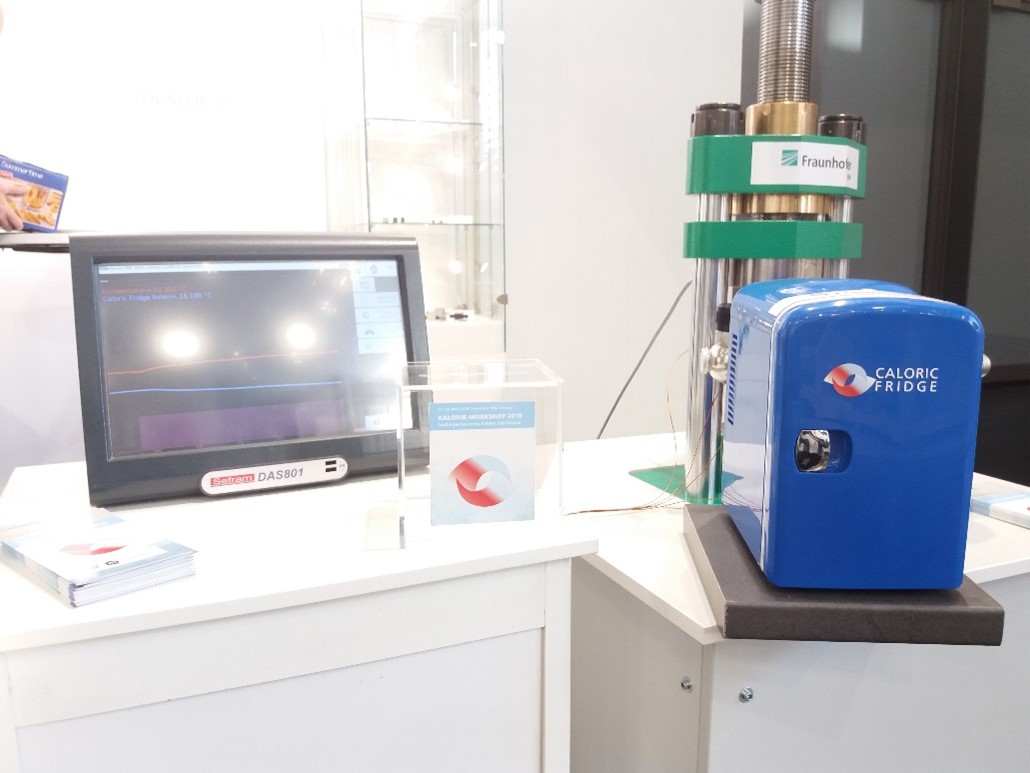

In the field of caloric systems, the department has been working for several years on the integration of magneto-, elasto- and electrocaloric materials in systems for the realization of efficient, refrigerant-free heat pumps and cooling systems. Here, the institute is pursuing a novel patented approach to heat transfer that allows the high material efficiency of caloric materials to be transferred to the cooling system. Based on this concept, system frequencies of up to 20 Hz could be realized with a magnetocaloric system in the laboratory - an order of magnitude higher than previously shown with other caloric system concepts in the literature. In addition, the first elastocalorically cooled mini-refrigerator was demonstrated at Chillvanta 2019, see Fig. 2.

IPM is also involved in various public projects in this field (BMWK project "MagMed II", BMBF project "ElastoCool", Fraunhofer project "MagCon"). In addition, Fraunhofer IPM participates in networks ("ZIM-Netzwerk Magnetokalorik"), has also organized a caloric workshop for the second time in spring 2019, and has conducted a consortium study ("InnoCool") on the state of the art in caloric technology in 2022.

Fraunhofer-Gesellschaft

Fraunhofer-Gesellschaft