Isabellenhütte Heusler GmbH & Co. KG

The company Isabellenhütte GmbH & Co. KG, Dillenburg is one of the most important manufacturers of electrical resistance materials and thermoelectric materials for temperature measurement as well as passive components for the automotive, electrical and electronics industries. The precision measurement technology division sets standards in the measurement of current, voltage and temperature in cars and trucks, but also in hybrid and electric vehicles as well as in industrial and regenerative energy generation systems.

As an internationally recognized specialist and technology leader, our innovative products repeatedly define the state of the art and underscore Isabellenhütte's technological and innovative competence. Decisive success criteria are the continuous development of novel products, technologies and manufacturing processes as well as the comparatively very high vertical range of manufacture. This extends from the production of the alloy through forming, etching and assembly technology to complex automatic testing and packaging machines in final inspection.

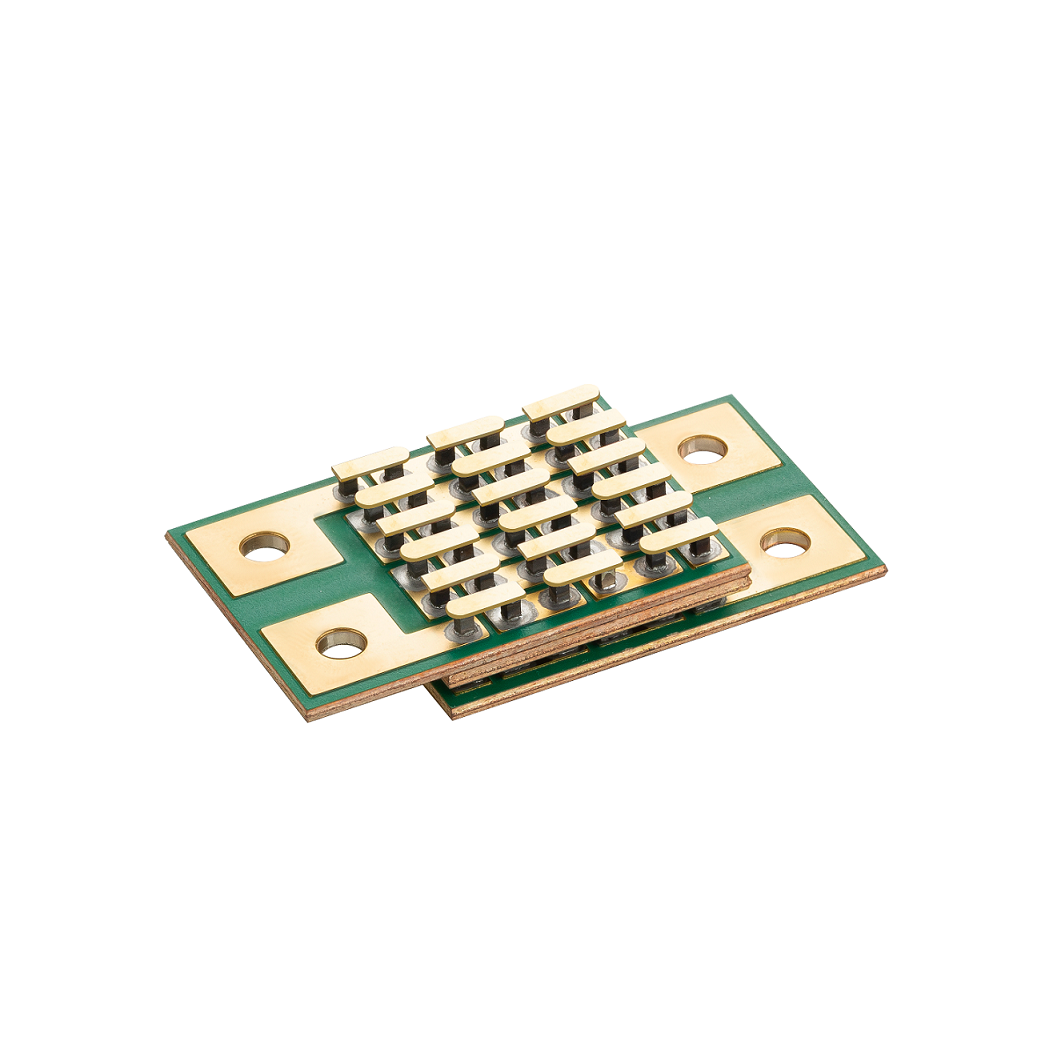

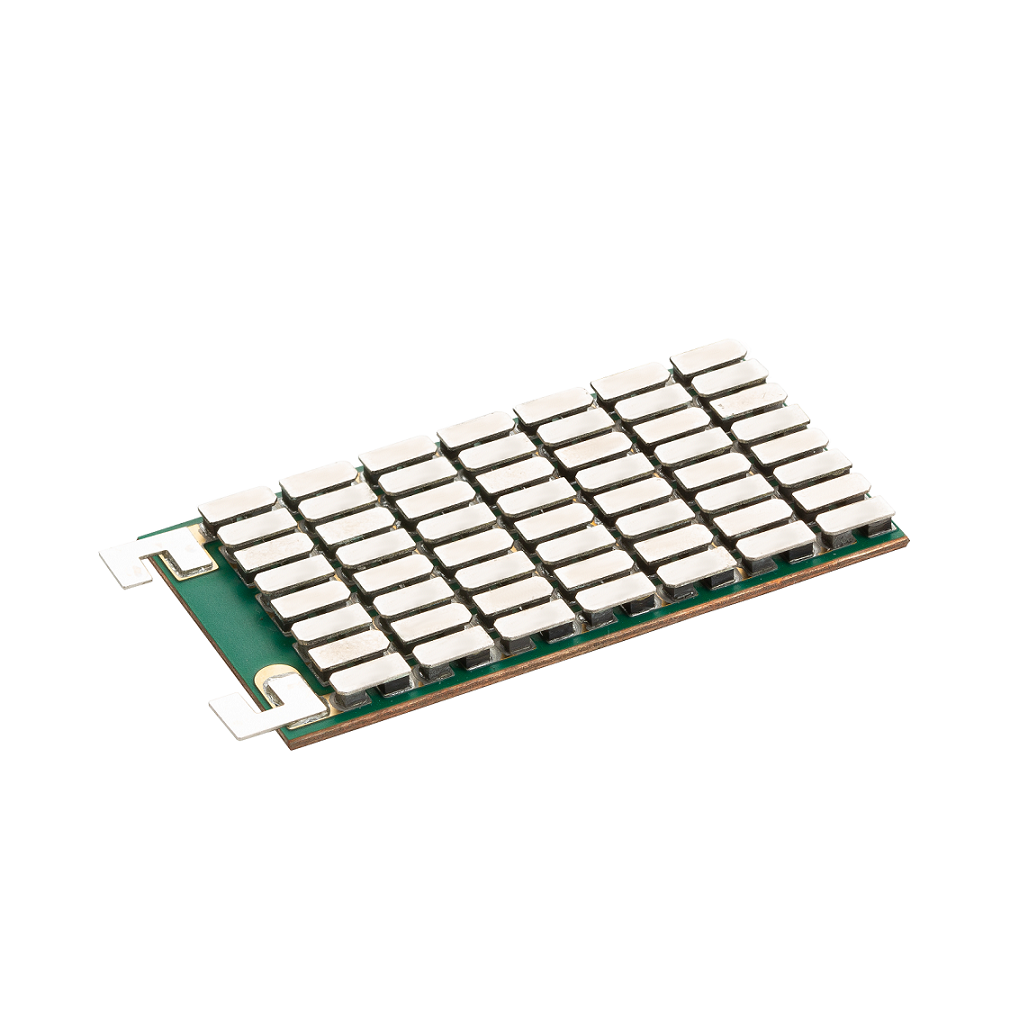

A current innovative development field of Isabellenhütte Heusler is the synthesis of thermoelectric materials, in particular the development of manufacturing and processing methods suitable for mass production as well as the development of innovative thermoelectric modules. In addition to traditional bismuth telluride modules, we see considerable market potential for thermoelectric waste heat utilization for temperatures up to 1000°C.

As part of these development activities, a complete pilot production line, for the manufacture of thermoelectric components from Halb-Heusler material, was installed at the Dillenburg site in 2017. In addition to a new melting furnace optimized for this class of material, this also includes various semiconductor processing units.

This makes it possible for the first time to investigate the production of thermoelectric half-Heusler materials under industrial conditions. In 2018, a fully automated assembling line for high-temperature thermoelectric module components was added to the production line for half-Heusler materials. This makes it possible to provide customer-specific high-temperature TEM prototypes in larger quantities on a technical scale. This assembling line for thermoelectric module components can also be used for the construction of high-quality bismuth telluride modules to complement the Halb-Heusler high-temperature technology to lower temperatures.

Fraunhofer-Gesellschaft

Fraunhofer-Gesellschaft